Hannover Trade Fair, 13 - 17 April 2015, Hall 7 – Booth E40 (VDMA shared booth)

The new GUARDUS MES “Energy Management” module of the specialist in manufacturing executions systems, GUARDUS Solutions AG offers significant support to industrial companies that have the task to design their production processes in a sustainable and environmentally sound way. The basis for this is the so-called direct energy consumption measurement, that is, the integrated collection, connection, and analysis of product, process, and energy data per manufacturing equipment and order. Due to the holistic data display, not only can energy-related indicators be calculated per manufactured product quantity at the push of a button, but the establishment of continuous improvement processes for energy savings according to the PDCA method is also a simple task. This transparency regarding energy is imperative for all those companies that want to make use of the tax privileges stipulated in the amended German Energy and Electricity Tax Act. However, the energy management system required in this context according to the ISO 50001 as well as the verifiable reduction of the energy intensity no longer represent a challenge for the users of the new GUARDUS MES standard module. Moreover, the energy management of the software manufacturer from Ulm complies with the specifications and recommendations of the valid VDMA standard sheet 66412 part 4. At the trade fair in Hannover, the new GUARDUS MES module will be presented to the broad public for the first time.

Even if several industrial companies make active efforts for a consistent optimisa-tion of their resource consumption, the energy factor is still treated negatively. Precisely on the shop floor, there is often a lot of ignorance regarding the actual energy consumption of the production processes in relation to the manufactured products. “When collecting the data about energy consumption, many companies concentrate on the points of intersection such as transformer stations or consumption counters in the buildings. However, these places of measurement do not offer information about the corresponding processes, production lines, or products. In order to take full advantage of the economic room for manoeuvre, the energy consumption must be recorded on a detailed form and transparently itemised. It is only in this way that a system of rules can be implemented for the continuous reduction of the energy consumption” said Andreas Kirsch member of the Managing Board at GUARDUS Solutions AG.

In this respect, the new Energy Management Module of the Manufacturing Execu-tion Systems GUARDUS MES offers significant help. From now on, the integrated MES database will administer not only all the data related to orders and machines, but also the direct, order-related energy consumption. Thus, the relations between the production order, manufactured quantity, scrap, as well as the machine, used tool, and the energy demand are presented in a transparent way.

GUARDUS MES Energy Management

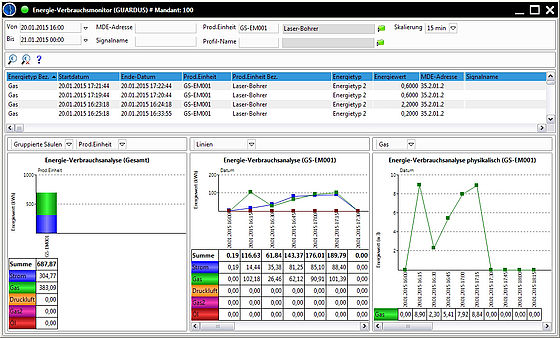

In order to determine the energy consumption per manufactured quantity, GUARDUS MES will be provided with various physical values (e.g. for electricity, gas, pressurised air, oil) and it will automatically convert them into kWh.

The GUARDUS MES energy consumption monitor will display not only the meas-ured values per machine, but also cumulated data for machine hierarchies.

By comparing the calculated values of energy consumption with the data from the machine journal, the collected data of the energy consumption can be assigned to the actually manufactured quantities (respectively to the machine state) per time unit.

The GUARDUS MES evaluations provide detailed effectiveness and efficiency indicators related to products, machines, and machine orders. The basis for the calculation is the VDMA standard sheet 66412 part 4 for the standard indicators.

In terms of a continuous improvement process, the user can implement a PDCA method according to the ISO 50001 via GUADUS MES action management in order to consistently reduce the energy consumption per manufactured product unit.