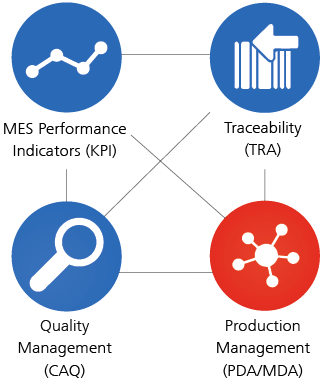

2. Production Management

In order to manufacture the highest quality products, production and quality management must work hand in hand. High quality can only come from having the greatest transparency at every step of production. With ZEISS GUARDUS, this transparency is achieved by integrating modules from the Production Management suite. ZEISS GUARDUS provides standardized integration to popular ERP / PPS systems. Production orders are generated and delivered directly to the production units, which gives production staff one interface to see what has been produced and what is next. Production staff then enter production information including number of units produced, units to be reworked and scraped which is then returned to the ERP / PPS system. If any issue arises, ZEISS GUARDUS provides for the traceability via batch, lot and serial number of every raw material and component.

ZEISS GUARDUS also focuses on the automatic collection of all machine and production data, as well as the central (SPC) statistical in-process control and online monitoring. Thus, it is possible to obtain machine data such as machine condition, quantity, time types and process parameters which can in turn be automatically assigned to the current production order. Additionally, all production-related employee information is made available directly to the production units to access work documents, drawings and test procedures, or corrective measures (complaints) and any other related information. This wealth of information is clearly displayed for each employee. The information can also be customized to reflect the requirements of every production unit.