The Cavity Manager of GUARDUS MES Ensures Process Stability and Safety

From now on, the new cavity manager of the Manufacturing Execution System GUARDUS MES offers complete transparency regarding the quality status of all of the tool nests of an injection moulding system. Depending on the user’s tasks, for example quality management, shift supervision, or mechanical engineering, the new function allows the user to visualise the information and warning messages for each injection moulding nest in colour as well as the display of all the pending inspections and the entry screen for the corresponding quality data per nest. The user is also informed about defective or blocked cavities as well as the repairs and corrective actions which have been taken. This ensures the monitoring of machine and quality states at the production line or inspection places. Moreover, the user receives reliable statements about the production time that is really necessary because only the nests that function impeccably are included in the calculation by the MES of GUARDUS Solutions AG. The result is the documentation and evaluation of the process, product, machines, tools, and cavities along the value chain.

During the manufacturing of injection moulding, the moulds give the desired form to the molten plastic. The hollow space in which the raw material is injected is called a nest or cavity. To offer maximum production efficiency, injection moulding tools normally have several nests. It is in this way that a vast number of parts are manufactured at second intervals and after they have been cooled, they are submitted to quality inspections in GUARDUS MES, for example in the context of the Statistical Process Control (SPC). If failures occur during this process, it is important to act quickly and if this does not happen, the number of rejected parts is very high and the incurring quality costs too.

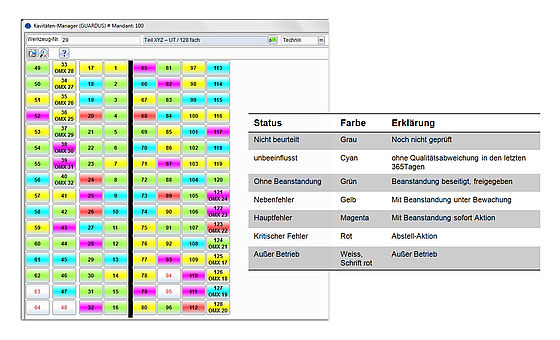

In order to be able to monitor the process stability and safety of the injection moulding systems, the MES specialist GUARDUS Solutions AG developed the new function ‘Cavity Manager’. This function displays the status of all the cavities of a tool not only from the technological point of view (the exact nest position), but also from the quality perspective (nest designation). Various colours and warning signals indicate seven different statuses: “still to be inspected”, “without quality deviations in the last x days”, “complaint eliminated”, “with complaint under observation”, “with complaint immediate action”, “corrective action”, and “out of order”.

Depending on the area where it is implemented, the Cavity Manager provides benefits related to the workplace. For the intuitive collection of quality data for each nest, the user will directly access the inspection data collection of GUARDUS MES via the graphical interface of the Cavity Manager. If the inspections end with a negative result, the user can mark the nest by pressing a button and can take the corresponding action (repair or blocking).

Via the new GUARDUS MES function, the shift responsible or the technical responsible can visualise all the critical defects and the corresponding actions. In the modules ‘Action Management’ and ‘Audit Trail’, all the activities carried out at a nest will be documented and will be directly available for the maintenance. The immediate implementation of the actions as well as the efficient escalation mechanisms will be supported by workflows. This is possible because of the complete integration of the ‘Cavity Manager’ into the whole functionality of the MES.