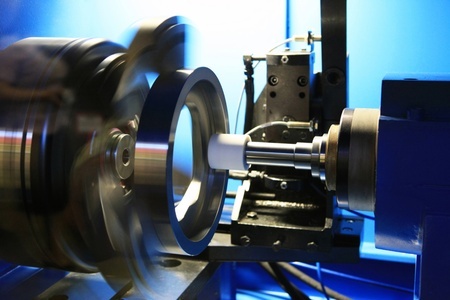

Metalworking

For many enterprises in the metallurgical industry, the demands for quality and market speed represent real challenges. On the international stage, the tolerances are expressed in mu and the highly precise manufacturing processes should be carried out efficiently and automatically. Without using IT systems, it would be impossible to comply with these requirements. In production, the CAQ, PDA, and MDA solutions are now more important than they have ever been. They assure an optimum manufacturing transparency and allow to intervene in the processes quickly and safety – regardless of on which continent.

- Continuous system platform for production, machine, and quality data

- Standard interfaces for the connection of machines, equipment, as well as testing systems

- Traceability from the raw material to the final product and the other way around

- Integrated quality inspections from goods receipt (inspection certificates) via the operator’s self-inspection up to the quality laboratory

- Online monitoring of the machine effectiveness, quality rates, etc.

- Plant layout, runtime diagram, and OEE cockpit

- Performance indicators cockpit for the analyses of malfunctions and defects and the improvement of efficiency