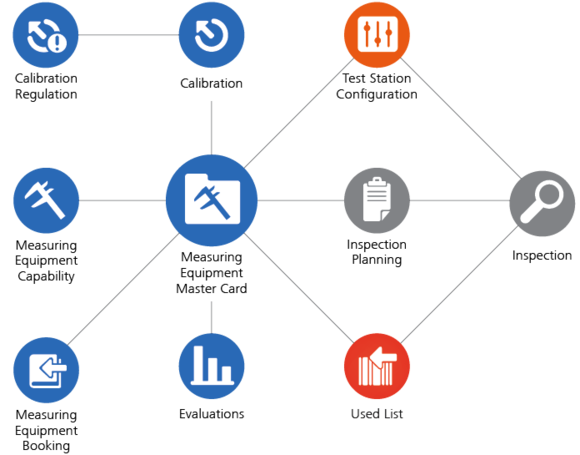

1.8. Measuring Equipment Management

The Measuring Equipment Management module in ZEISS GUARDUS ensures the regular control and calibration of the test equipment used for manufacturing and production control and takes care of standards conformity of all test equipment capability. Organized according to types and groups, the entire usage and calibration history of test planning, maintenance and evaluation is stored in the corresponding test equipment identification card. The special advantage that grows with this process is that the test intervals can be better adapted, be it reduced or varied, to the actual state of the test equipment. Through the integration of the test equipment database into the inspections carried out in the production, ZEISS GUARDUS supports the obligation to prove which test equipment was actually used for a specific test and provides the immediate test equipment traceability.

“Until now we executed the calibration of all test equipment in a certain period of time in the year. Due to our intense development we could manage this kind of procedure only under time pressure. Now we can forecast when and what kind of calibration has to be executed.“

Michael Winkler

Director of Quality Management

Wilhelm Layher GmbH & Co. KG

- Measuring Equipment Master Cards

- Inspection Intervals

- Booking History

- Schedule List

- Measuring Equipment Calibration

- Measuring Equipment Capability

- Integration into Inspection Planning and Data Collection

- Usage Certificate