2.5. Maintenance

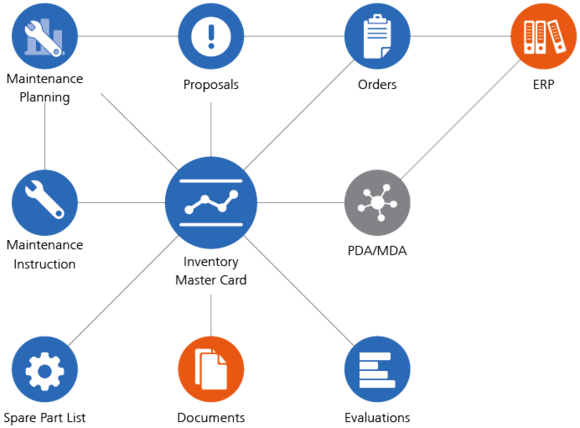

All the data required to ensure the proper maintenance of production facilities are included as the basic building blocks of the ZEISS GUARDUS Maintenance module. Machines, production units and tools scheduled for maintenance are managed by virtual master cards through a user-friendly interface. Corresponding spare parts lists and maintenance plans are also integrated for easy referencing. The continuous care of items is coordinated through version-controlled maintenance plans. Administrators schedule maintenance plans that can be either cyclical, or optionally, triggered by conditions or events. Individual check lists, spare parts lists and bills of materials describe the details of tasks to be carried out, thus becoming the basis for any maintenance plan.

When maintenance work is concluded, the order receives a 'completed' status and the next maintenance is automatically scheduled. For more detailed notification, end-users create maintenance and repair reports and optionally enter the real costs incurred.

- Maintenance Plans

- Bill of Materials and Spare Part Lists

- Checklists

- Maintenance and Repair Orders

- Cost Transparency

- ERP/PPS Integration