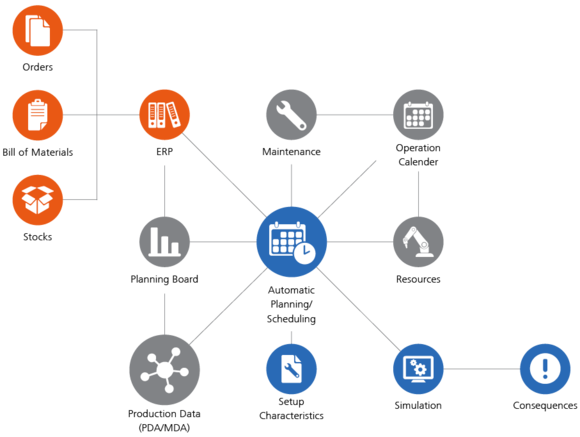

2.9. Planning/Scheduling (APS)

Only a few steps separate the office from the production plant and yet the flawless information flow between the business and production process does not always function smoothly. In these times, when cost optimisation, compliance with the deadline at all costs, exact statements about delivery dates and a smooth order flow are more important than ever, Manufacturing Execution Systems (MES) play a key role for the interconnectedness between the production and management levels. GANTTPLAN achieves this vertical integration and thereby the interconnectedness between the ERP and shop floor.

- Reduced Time Effort Compared to Traditional Planning

- Multiple Resource Planning (Machines, Personnel, Tools, Devices, Material...)

- Planning Based on Real Production and Order Situation

- Rapid Reaction to the Current Production Situation Due to Quicker Algorithms and Integration into MES

- Weighting of Target Criteria for Individual Plan Optimisation

- Scheduling in Case of Bottleneck Production

- Representation of Nets of Orders and Critical Path

- Graphical View of Capacity Load

- Simulation with Various Periods of Time, Weighting Criteria and Optimisation Suggestions with a Calculation of Economic Impact

- Adjustable to Customers’ Needs