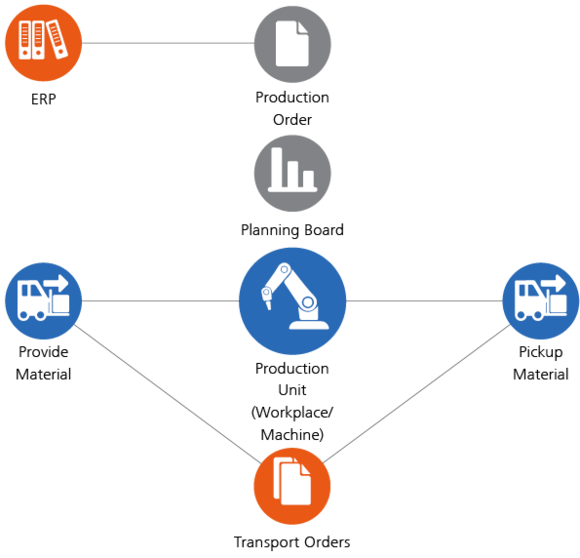

2.8 Production Logistics

The Production Logistics module of ZEISS GUARDUS guarantees the highest efficiency for the material flow. The main element is the control of the intra-logistic processes on the basis of actual data. Synchronised with the current operations, the right material will be supplied or removed to/from the machine/production unit at the right moment for each manufacturing order. This is valid not only for raw materials, but also for produced material stocks on the shopfloor – the so-called ‘Work in Process’ (WIP). The processing of in-time logistic information makes sure that the interlinked operations can be started at the right moment and the whole order can be executed in-time. The seamless integration into the operational business world as well the surrounding systems of transport and warehouse management allows for the necessary process safety. Depending on the container unit and active production cycle, the machines and production units determine the transport frequency of the supply as well as the removal of material, thereby improving the agility in the production.

- Online Information for the Smooth Calculation of the Material Demand

- Flexible Control of the Material Request via Various Parameters

- Comfortable Integration Procedures for the Connection of the Surrounding Systems of

- Transport and Warehouse Management Seamless Communication Flows by Using Mobile Devices

- The Most Modern Techniques of Collecting the Ware – Barcode, Data Matrix Code or Chip Card and RFID

- Intuitive Transport Order Board for the Efficient Execution of Pick-up Orders